Industrial Blowers in Modern Manufacturing

Industrial Blowers as Intelligent Airflow Engines

In today’s industrial landscape, industrial blowers have evolved far beyond basic air-moving devices. They now function as intelligent airflow engines, enabling precise control, continuous operation, and optimized energy utilization across a wide range of industrial processes. From heavy manufacturing to advanced environmental engineering, the role of industrial blowers is foundational, measurable, and mission-critical.

As industries pursue higher productivity, reduced energy intensity, and smarter system integration, airflow solutions must deliver not only power but also predictability, efficiency, and scalability. Among the most widely deployed technologies, side channel blowers, medium pressure blowers, and maglev turbo blowers stand out as three core categories that collectively address the full spectrum of industrial airflow requirements.

This article provides a comprehensive, system-level overview of how these three blower technologies function in industrial environments and how they generate tangible operational value.

Side Channel Blower: Intelligent Stability for Continuous Industrial Processes

Advanced Operating Logic and Structural Design

A side channel blower operates on a regenerative airflow principle. Air is repeatedly accelerated by a high-speed impeller within a side channel, incrementally increasing pressure through controlled energy transfer. This design results in exceptionally stable airflow, making the technology ideal for applications where consistency is non-negotiable.

Key engineered advantages include:

- Oil-free compression, ensuring clean and uncontaminated air

- Non-contact internal operation, minimizing mechanical wear

- Compact modular construction, enabling flexible installation

- Low pulsation and vibration, supporting sensitive processes

These characteristics allow side channel blowers to operate continuously with predictable performance profiles.

High-Value Industrial Applications

Side channel blowers are widely implemented in systems where operational continuity and air purity are essential:

- Wastewater treatment aeration systems for biological processing

- Pneumatic conveying of powders and lightweight materials

- Vacuum holding and suction systems in automation and packaging

- Aquaculture aeration for oxygen transfer efficiency

- Medical and laboratory airflow systems

In these environments, stable pressure and uninterrupted airflow directly translate into improved process reliability and reduced operational risk.

Process-Level Value Creation

From an industrial systems perspective, side channel blowers provide baseline airflow intelligence. They enable long-duration operation with minimal intervention, supporting lean maintenance strategies and predictable lifecycle performance.

Medium Pressure Blower: Adaptive Power for Dynamic Industrial Systems

Performance Architecture and Functional Flexibility

A medium pressure blower is engineered to deliver higher static pressure than conventional centrifugal fans while maintaining substantial airflow capacity. Through reinforced impeller geometry and optimized aerodynamic design, this blower category supports dynamic airflow demands without sacrificing stability.

Core performance attributes include:

- Expanded pressure range suitable for high-resistance systems

- Robust mechanical structure for industrial-grade durability

- High adaptability to fluctuating operating conditions

- Consistent output under variable load profiles

This makes medium pressure blowers a critical component in complex industrial networks.

Strategic Industrial Use Cases

Medium pressure blowers are frequently deployed in applications where airflow must overcome system resistance or operate under changing conditions:

- Combustion air supply for industrial furnaces and burners

- Flue gas extraction and exhaust handling

- Industrial drying and thermal processing systems

- Dust collection and filtration in manufacturing plants

- Material conveying across extended pipelines

Their ability to maintain performance under stress conditions ensures uninterrupted production flow.

Operational Impact and Energy Balance

Medium pressure blowers function as adaptive airflow assets. When correctly integrated, they balance pressure capability with energy efficiency, making them a preferred solution for mid-to-high demand industrial environments that require operational resilience.

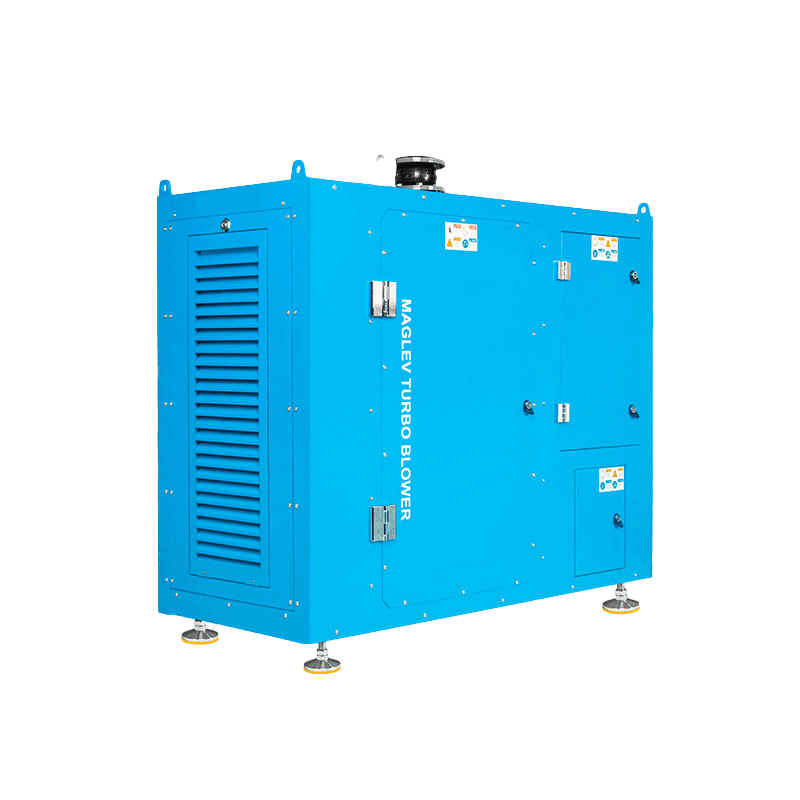

Maglev Turbo Blower: Efficiency Through Magnetic Levitation

Next-Generation Magnetic Levitation Technology

Maglev turbo blower represents the convergence of advanced mechanical engineering, digital control, and energy optimization. By employing magnetic levitation bearings, the rotor operates without physical contact, eliminating friction and mechanical loss entirely.

Combined with high-speed permanent magnet motors and intelligent control algorithms, maglev turbo blowers deliver:

- Ultra-high rotational efficiency

- Zero mechanical wear

- Extremely low vibration and acoustic output

- Real-time adaptive airflow control

- Exceptional partial-load performance

This technology aligns seamlessly with smart factory and Industry 4.0 initiatives.

High-Impact Industrial Applications

Maglev turbo blowers are purpose-built for large-scale and energy-intensive operations:

- Municipal and industrial wastewater treatment aeration

- Biological fermentation and biochemical processing

- Petrochemical and chemical production

- Steel, cement, and power generation industries

- Centralized industrial air supply networks

In these applications, airflow efficiency directly affects operational cost structures and environmental performance.

Lifecycle Optimization and Strategic ROI

From a total cost of ownership perspective, maglev turbo blowers redefine value creation. Despite higher upfront investment, they deliver:

- Significant long-term energy savings

- Minimal maintenance requirements

- Extended operational lifespan

- Lower system downtime

For enterprises focused on sustainability, automation, and data-driven optimization, maglev turbo blowers represent a future-ready infrastructure investment.

Comparative Intelligence: Matching Blower Technology to Industrial Demand

Airflow and Pressure Capability

- Side Channel Blower: Stable airflow, moderate pressure, continuous-duty optimization

- Medium Pressure Blower: Enhanced pressure range, system adaptability

- Maglev Turbo Blower: High-flow, ultra-efficient, large-scale optimization

Energy Efficiency and Control Precision

Energy efficiency increasingly defines industrial competitiveness:

- Side channel blowers provide efficient baseline airflow

- Medium pressure blowers offer balanced performance across variable loads

- Maglev turbo blowers deliver industry-leading efficiency with intelligent modulation

Maintenance, Reliability, and Predictability

- Side channel blowers reduce maintenance through oil-free design

- Medium pressure blowers provide robust mechanical reliability

- Maglev turbo blowers virtually eliminate wear-related failures

Industrial Blowers as Data-Driven Process Enablers

Modern industrial blowers are no longer passive components. They actively influence:

- Process stability

- Energy consumption patterns

- System automation

- Environmental compliance

When integrated with intelligent controls, blowers become data-enabled process enablers, supporting predictive maintenance, real-time optimization, and long-term operational planning.

Conclusion

Industrial blowers form the invisible backbone of modern industry. Through intelligent design and application-specific engineering, side channel blowers, medium pressure blowers, and maglev turbo blowers were all developed to meet the needs of various industries.

By aligning blower technology with process requirements, industries unlock higher efficiency, improved reliability, and sustainable operational growth.