Key Specifications You Should Know About Ring Blowers

In industrial fluid system design, selecting the wrong ring blower often leads to endless maintenance and excessive energy costs down the line. Rather than focusing solely on model and price, it’s crucial to delve into its core technical specifications. This article skips the superficial details and guides you through the key parameters—from pressure and flow rate to thermal management—that truly determine system longevity, helping you make professional and informed selection decisions.

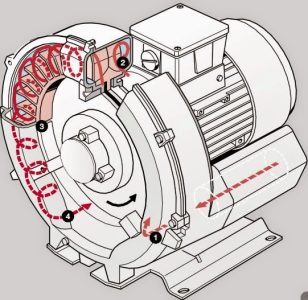

1. Fundamentals: The Side Channel Principle

Unlike positive displacement pumps, ring blowers operate on a non-positive displacement principle. An impeller accelerates the air within a ring-shaped housing, converting kinetic energy into steady, pulse-free pressure.

While the concept is simple, the execution is all in the details. A thorough spec review ensures the blower aligns with your specific duty cycle, environmental variables, and safety mandates.

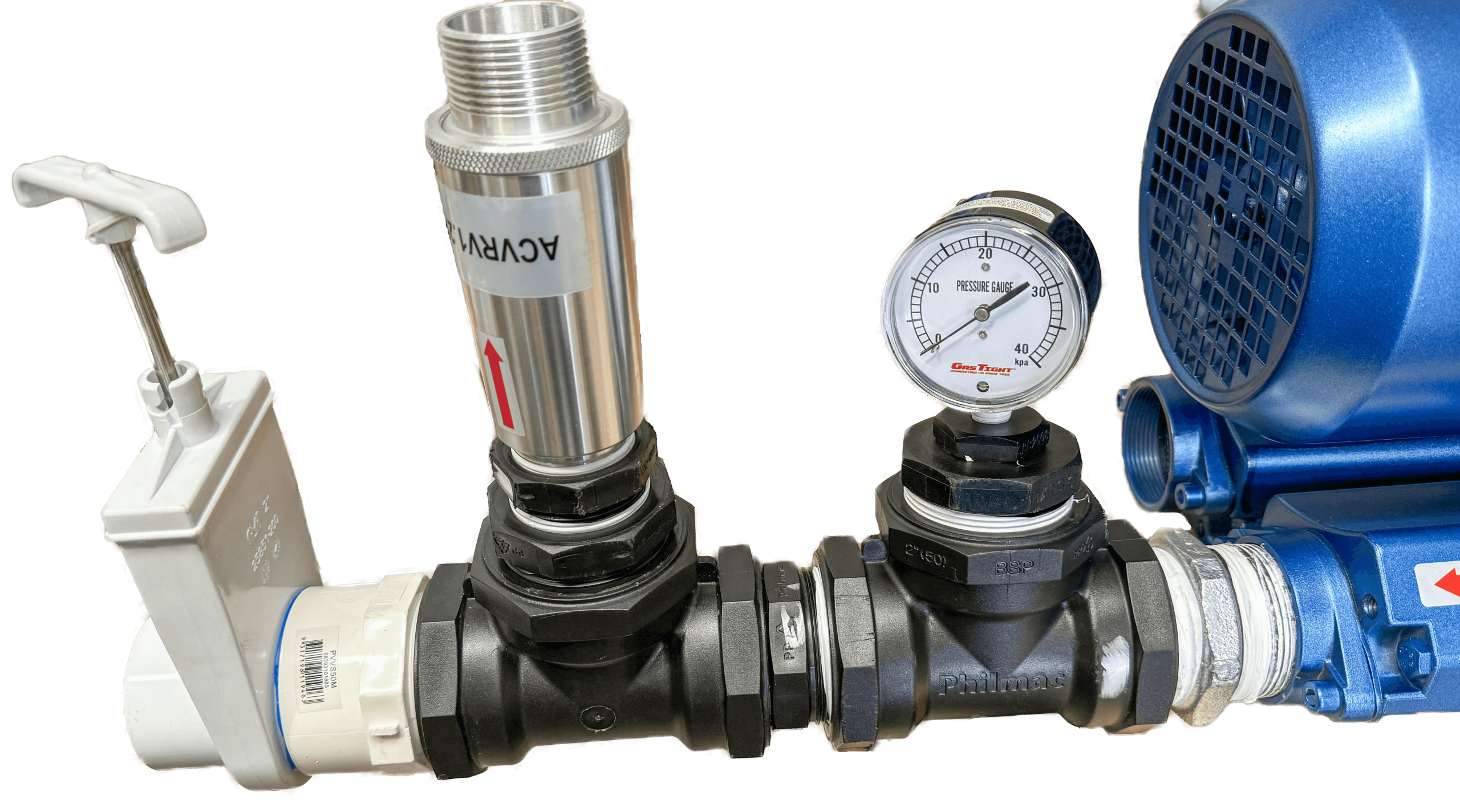

2. Pressure Capabilities: Static vs. Vacuum

Maximum Static Pressure

This is arguably the “make or break” spec. Measured in mbar or kPa, static pressure dictates whether the blower can punch through system resistance—think piping friction, fine-bubble diffusers, or clogged filters. High-performance models utilize tighter tolerances and optimized impeller geometry to maintain flow even as backpressure climbs.

Vacuum Performance

If your application involves suction—such as pneumatic conveying or industrial extraction—the maximum vacuum rating is your primary KPI. If your system oscillates between pressure and vacuum, you’ll need a blower specifically balanced for dual-mode stability.

3. Airflow and Volumetric Efficiency

Rated Flow Capacity

Airflow (measured in m³/h or CFM) is never a standalone number; it is always relative to a specific pressure point. A common mistake is looking at “Free Air Displacement” (zero pressure) and assuming it holds under load.

Mastering the Performance Curve

A blower’s curve is its “fingerprint.” It reveals the relationship between pressure and volume. When specifying, aim for the “sweet spot” in the middle of the curve. Running too close to the “dead head” (maximum pressure) or “run out” (maximum flow) leads to excessive heat and a significantly shorter motor life.

4. Electrical and Motor Integrity

Power Ratings and Thermal Overhead

Whether it’s kW or HP, the motor must be sized for the worst-case scenario. While oversizing is inefficient, an undersized motor will struggle with thermal dissipation during continuous duty.

- Voltage/Frequency: Ensure compatibility with local grids (50Hz vs. 60Hz), as frequency changes directly affect the blower’s RPM and, consequently, its performance.

- Protection Classes: For harsh environments, look for IP55 ratings or higher and Class F or H insulation to safeguard against dust, moisture, and heat.

5. Efficiency and The “Green” Bottom Line

Specific Power Consumption

True efficiency is measured by how much energy it takes to move a specific volume of air at a specific pressure. Aerodynamically optimized blowers might have a higher upfront cost, but they pay for themselves through lower utility bills and a reduced carbon footprint.

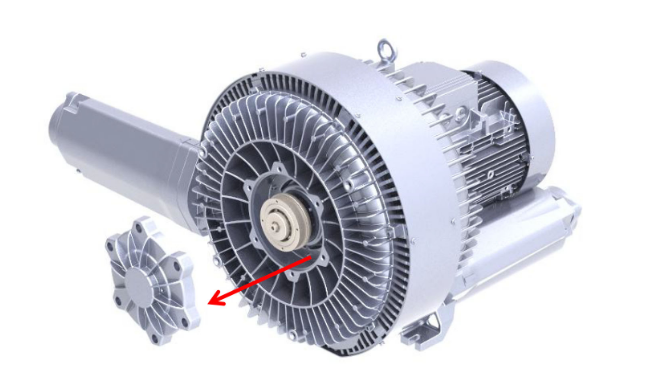

Thermal Management

Heat is the enemy of mechanical longevity. Premium blowers utilize high-grade aluminum alloy housings with integrated cooling fins to dissipate heat efficiently, ensuring the unit remains stable during 24/7 operation.

6. Mechanical Design and Materials

- Housing & Impeller: Die-cast aluminum is the industry standard for its strength-to-weight ratio and heat conductivity. For corrosive gas handling, check for specialized coatings (like PTFE).

- Bearings: These are the only wearing parts. High-precision, sealed-for-life bearings are essential for minimizing vibration and extending maintenance intervals.

7. Acoustics and Workplace Safety

Ring blowers are naturally quieter than many other compressor types, but noise is still a factor. Look at the dB(A) ratings. If your installation is in a noise-sensitive area, check if the unit has integrated silencers or if the manufacturer offers external acoustic enclosures that won’t choke the airflow.

8. Compliance and Duty Cycle

Continuous Duty (S1)

Industrial processes don’t take breaks. Ensure your blower is rated for 100% duty cycle. Cheap alternatives often overheat if run for more than a few hours at a time.

Certifications

In regulated sectors, certifications like CE, UL, or ATEX aren’t just “nice to have”—they are legal requirements. For explosive environments, an ATEX-certified spark-proof design is non-negotiable.

9. Environmental Factors

- Ambient Temperature: Don’t forget to account for the “room” temperature. High ambient heat requires derating the motor’s capacity.

- Altitude: At higher elevations, air is thinner. This reduces both cooling efficiency and the mass flow of the air being moved.

Conclusion

Selecting a ring blower isn’t about finding the cheapest unit that fits the pipe; it’s about matching the physics of the machine to the demands of your process. By prioritizing the performance curve, thermal management, and motor integrity, you ensure a system that is efficient, quiet, and—above all—reliable.